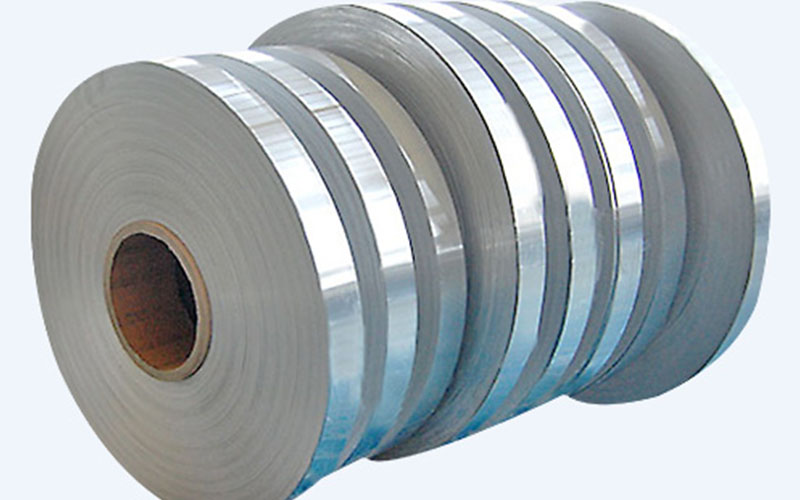

Thin Aluminum Strips VS Copper Strips for Transformers

Copper and aluminium strips are two regular materials used for transformer winding. Copper is the traditional material, but it’s being replaced by thin aluminum strips. Aluminium strip 1mm has advantages of good conductivity and low cost. Silver has the highest conductivity, followed by copper, gold, aluminum and nickle. High costs of silver and gold make it impossible for them to be used as industrial raw materials, left only copper and aluminum. Copper is much more expensive than aluminum, and many transformer manufacturers choose aluminum featuring small volume, light weight, good insulation effect, zero pollution and excellent water proof performance. Transformers of 1060 aluminum strip winding boast stable operation, low maintenance cost and small noise, applied widely in tall buildings, underground stations, shopping malls, neighbourhood areas and hotels in both dry and wet districts.

In comparison to copper strips, the advantages of 1 inch aluminum strips include light weight, convenient transportation and low cost. But they breaks easily if not have been manufactured by advanced processes. Moreover, aluminium strips have a stronger resistance than copper, and they gets hot more quickly, which will do harm to properties of a transformer. Copper strips, on the other hand, boast low resistance, high efficiency and slow temperature rises, meeting all key requirements of a stable transformer. Their weaknesses lie in much heavier weight and higher price.

However, experts believe that aluminium strips can perform better than copper ones if dealt with with proper processes. Take the toroidal transformer for example. A toroidal transformer is a special transformer with a complicated process. The copper resistivity is smaller than the aluminum resistivity. When designing a toroidal transformer, the current density can be reduced to meet the requirements of loss and short circuit resistance. Copper transformers of the same power are smaller than aluminum transformers, and others can be designed according to one standard. The most important thing is to solve the problem of welding and oxidation of aluminium strips. It requires special welding technology to cover the entire aluminum wire welding head to prevent oxidation, and the overall performance is better than copper wire transformer.

Reprinted from https://www.aluminum-coil.net/thin-aluminum-strips-vs-copper-strips-for-transformers.html

评论

发表评论