What causes damages to aluminium round discs

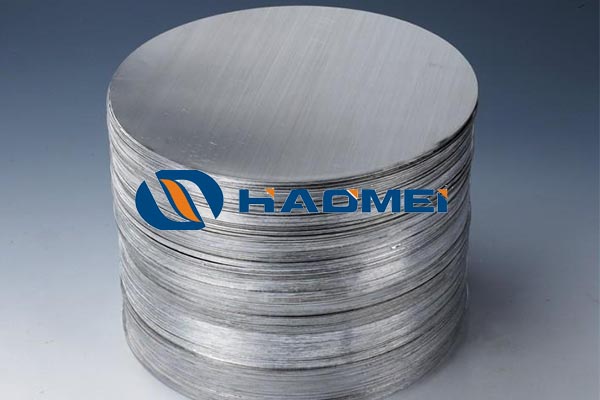

Aluminium round discs are also known as an aluminum round disc, referring to aluminum wafers made of aluminum as the main raw material and mixed with other alloying elements. The aluminum round disc is a round type obtained by embossing an aluminum ingot, and is divided into different grades, specifications, and states according to the use. There is a certain amount of solid metal particles in the aluminum disc. When we use aluminum discs, sometimes the surface will be damaged. And what are the causes?

1. When the metal flows through the working belt during the kneading process, a large amount of segregation floating objects or strong metal particles adhere to the surface of the working belt on the surface of the aluminum round disc, which may cause scratches on the surface of the aluminum wafer.

2. There is any debris on the work belt during work, so that the surface of the work belt is injured during the kneading and aluminium round discs are scratched.

3. The speed is too fast to form aluminum disc bumps;

4. The aluminium round discs collide with each other or knead to form damage during transportation.

Aluminum round disc pieces and aluminum alloys are among the most economical materials available today. The current production and use of aluminum is second only to steel, making it the second largest metal for human applications, and the resources of aluminum are very rich. Aluminum wafers and aluminum alloys are widely used in the manufacturing industries of airplanes, automobiles, trains, and ships. Pure aluminum is very soft with good ductility, and can be drawn into filaments and rolled into foil, used in the manufacture of wires, cables, the radio industry, and the packaging industry.

评论

发表评论