1050 aluminium embossed sheet application and price

1050 aluminium embossed sheet is made of high-purity 1050 aluminum ingot that goes through continuous casting and rolling until the ingot bulk turns into aluminum rolls of a given thickness and width. Then such a roll passes a roller with patterns which are further embossed onto the coil surface, becoming embossed aluminum coil. The coil is further cut into sheet pieces of desired sizes. By then the production process of 1050 aluminum embossed sheets are finished.

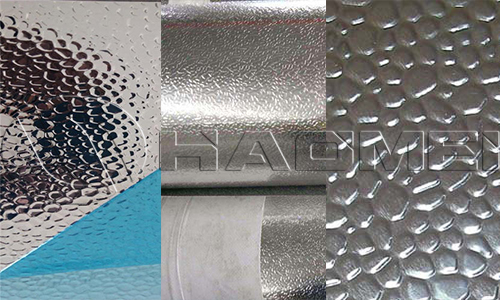

The 1050 embossed aluminum sheet finds its applications in packaging, building, wall cladding and industrial production based on varying patterns and thicknesses. The patterns for the sheet cover pebble, stucco, hammer, diamond etc. A pebble aluminium sheet has multiple functions of decoration and skid resistance, and it serves as anti-slip panels sometimes. A stucco embossed aluminum sheet is more frequently found as an insulation material, for its unique pattern type brings the insulation property of 1050 aluminum sheet into full play. Stucco 1050 sheets can also be used in packaging, which part is played by diamond aluminium sheets most of the time, for the sheets boast beautifully arranged diamond patterns. Hammer embossed aluminum coil is often of a reflective surface, as it serves as a regular material for lamp covers and camera reflective panels. The thickness of 1050 embossed aluminum plate ranges from 0.01mm to 3.0mm, and width 800mm to 1226mm.

Different embossed aluminum sheet suppliers offer varied price for 1050 sheets. In spite of this, we can provide a price scope here. 1050 embossed aluminum sheet metal is about $300 more expensive than mill finish 1050 aluminum sheet, largely around $2400 per metric ton. If you need a specific price, welcome to send details to april@aluminumhm.com or leave a message at “contact us” directly!

Reprinted from https://www.aluminum-coil.net/1050-aluminium-embossed-sheet.html

评论

发表评论