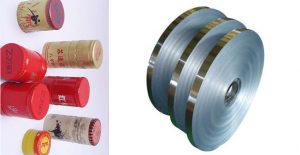

Aluminium Capping Strip

The alloys of aluminium capping strip include 1000 series, 3003 and 8011. In accordance with practical needs, the strip are usually processed into thickness between 0.20mm and 6.8mm under states of O, H14, H16, H18, H22, H24 and H26 etc.

Aluminium capping strip can be made into bottle caps of simple appearance, delicate design and neat printing. In comparison with plastic materials, aluminium caps have obvious advantages. They can realize high sealing effect of wine bottles, which is a feature that plastic caps lack in. Aluminium caps cost a half less than plastic caps, because it takes less steps to process aluminium capping strip into caps of given shape and design. What’s more, the recyclable system for aluminium products are so mature that aluminum caps can be reused almost by 100%. They turn out to be environmental in usage, too. Plastics tend to adsorb dust and powder in the air and lead to serious pollution to wines or spirits. Aluminum has no such problem. It neither contains nor adsorbs harmful materials. After being anodized, there’s little chance for it to react with other elements, either. Healthy, environmental, recyclable and cheap, no wonder aluminium capping strips have won so much popularity.

However, aluminium capping strips are not perfect. After being processed into caps, they show uneven colors on the cap side. The coated layers tend to peal off after a period of time. Besides, they are usually made into similar shapes with similar designs. Fortunately, experts say that these problems will be solved with technology development in the future. Therefore, aluminium capping strips still have a promising future.

Reprinted from http://www.aluminio.cn/aluminium-capping-strip/

评论

发表评论