Aluminium Slug for Tubes Manufacturers In China

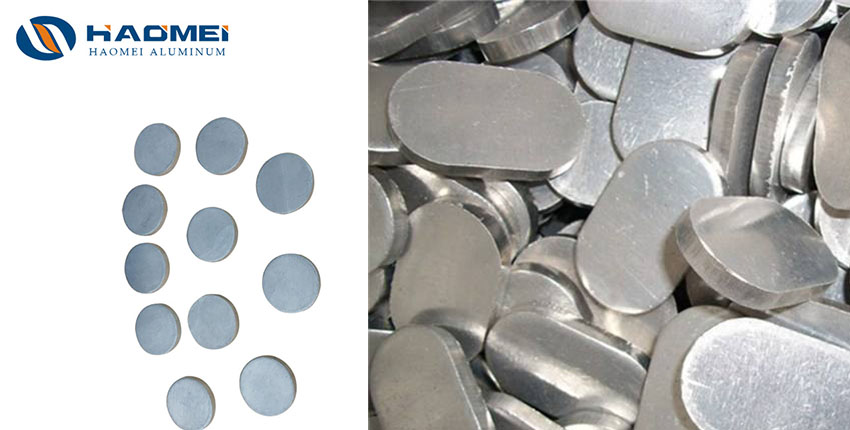

Established thirty years ago, Haomei is one of the most well-known aluminium slug for tubes manufacturers in China. It supplies 1050 and 1070 aluminium slugs of A class. Thickness of the slugs ranges from 2mm to 30mm and diameter from 10mm to 200mm. General shapes include flat round, dome, oval, rectangle, round with hole etc. Finished slugs have a tensile strength of 70Mpa and yield strength 35Mpa. Their elongation reaches as much as 42%. For years our aluminium slug for tubes have been made into various end products, such as collapsible tubes, pharmaceutical tubes, cosmetic containers, aerosol cans, aluminum bottles, capacitor housings, auto oil filter shells, markpen tubes, bottle caps and so on.

Among influential aluminium slug for tubes manufacturers, Haomei has strict quality control for its products. All raw materials go through at least nine processes before being finished for packaging. Aluminum ingots are first melted and then made into narrow aluminum strips or belts through rotary casting. To reduce the thickness of the belts, they experience successively hot rolling and cold rolling. The former process helps to reduce their thickness by 40% to 70%, and the latter further reduces another 30% to 50%. By now the strips finally reach a given thickness equal to that of slugs to be produced, which means they are ready to enter a stamping machine. The machine punches aluminium slugs out of the strips. During the next annealing step, hardness of the slugs is weakened to meet later manufacturing requirements of tubes and cans. The following process is surface treatment, including sandblasting, vibrating and tumbling, the purpose of which is to make slug surface smooth. Then finished slugs go through a strict inspection process consisting of gauge, mechanical test and surface quality. Now the production of aluminium slug for tubes is finally finished.

Reprinted from https://www.aluminum-coil.net/aluminium-slug-for-tubes-manufacturers-in-china.html

评论

发表评论