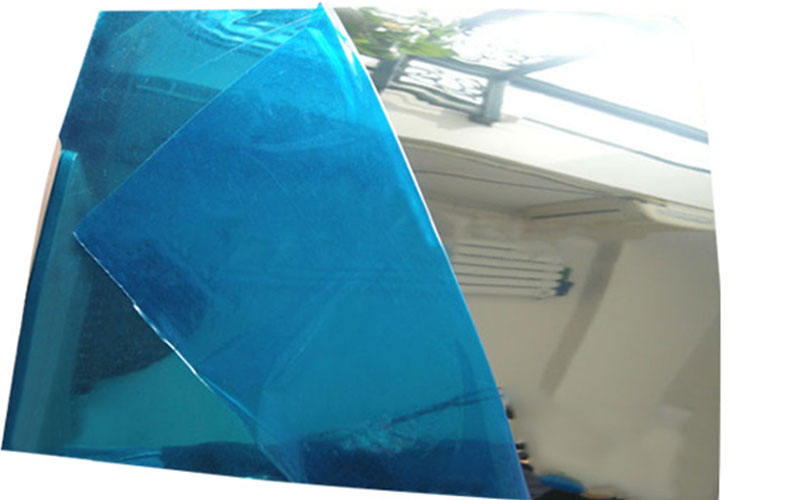

Polishing Methods of Aluminium Mirror Finish Sheet

As known to all, aluminium mirror finish sheets are obtained by polishing aluminum substrates of given alloys and tempers. There are roughly three polishing methods: buffing, buffing&chemical polishing and electronic chemical polishing with the previous two polishing steps. Needless to say, the last method produces the highest quality. Each of the methods can be further divided in practice. Take buffing for example. There are coarse buffing and precise buffing, hard buffing and soft buffing, hair felt buffing and wool buffing as well as variation in types of polishing grease etc. It’s worth mentioning sheets of any strength can be processed into mirror polish aluminum by polishing.

The most frequently adopted polished method for mirror finish anodized aluminum sheet, however, is through a polishing machine. The first step is to selectively and effectively remove peaks on the surface of the sheet to be polished. This can be realized by placing the sheet in an aqueous solution of sodium nitrate, which stimulates the formation of a passivation film and its partial destruction. Since the electrolyte used is passivating, a passivation film is formed on the working surface of the anode. The film completely covers the sheet and thus suppresses the electrolysis. However, due to the action of the abrasive distributed on the surface of the viscoelastic body, the passivation film formed on the peak is destroyed when it is scratched, and the electrolysis current is thereby passed, thereby dissolving the exposed peak.

Reprinted from https://www.aluminum-coil.net/polishing-methods-of-aluminium-mirror-finish-sheet.html

评论

发表评论