How to Install Embossed Aluminum Sheet

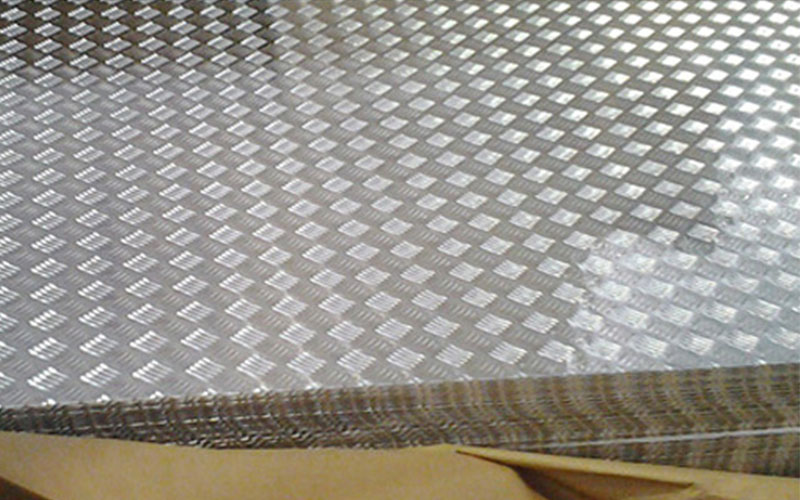

Embossed aluminum sheet has become ubiquitous in our daily life. Stucco embossed aluminum sheet pieces may be used as wall cladding for offices and inner walls for fridges. Aluminium cheaquered plate 5 bar can be used for wind power generation and as anti-skid plates at entrances of shopping malls and escalators. Embossed aluminium covers such a wide scope of application because of its light weight, good corrosion resistance and excellent anti-skid performance. How to install embossed aluminum sheets properly?

1. Elastic sealants can be applied in the structure treating of an embossed aluminum sheet, the top of the horizontal part, the ends and the intersection of two different materials.

2. A gap from 5 to 10mm between two stucco embossed aluminum sheets should be left treated with an elastic material such as a rubber strip or a sealant.

3. Steel-type skeletons can be first drilled a hole in the position of the screw with an electric drill. The hole diameter should be determined according to the specifications of the screw, and then the pattern aluminum strip should be tightened with a self-tapping screw. Embossed plates can be screwed onto a wooden skeleton with wood screws.

4, Screw heads should be well treated so that they will not be revealed. One end of an embossed aluminium sheet is fixed by screws, and the other end inserts a little to cover the screws perfectly. Gaps of 6mm width between cheaquered plates form lines of vertical concave corners, enriching facade of a building and creating a horizontal effect.

Reprinted from https://www.aluminum-coil.net/how-to-install-embossed-aluminum-sheet.html

评论

发表评论