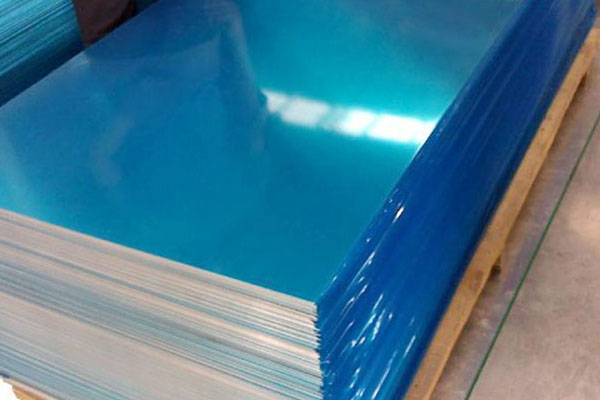

Mirror lamin aluminum sheet

The full name of mirror lamin aluminum sheet should be laminated aluminium mirror sheet, which can be divided by materials and process methods. Lamination methods are various, too.

A laminated aluminium mirror sheet refers to a mirror sheet with a protective film. By materials there are 1050, 1060, 1070, 3003, 3004, 5005 and 5052 aluminum mirror sheets. The hardness and anodizing effect of those alloys get stronger successively. 5000 series aluminum sheets are regarded as an excellent material for anodizing. Mirror finish anodized aluminum sheets of such alloys are very popular with cell phone manufacturers who make the sheets into cell phone back shells of various colors and fashion styles. By process methods there are mirror finish anodized aluminum sheets and polished aluminum sheets. The former goes through an extra process of anodizing, and the latter only gets polished. Needless to say, anodized sheets have better performance in many aspects.

The film of a mirror lamin aluminum sheet is a thin sticky film of 0.03mm to 0.07mm thick, functioning to protect the sheet from being scratched or damaged on the surface. One side or both sides can be filmed up to specific requirements. Generally the price for film coating ranges between 1.8RMB to 2.5RMB per pieces. Large quantities of orders enjoy free film coating by most manufacturers. You just need to ask them to have the sheets coated before delivery. Costs for film coating with not be charged, and possible damages to sheet surfaces during secondary processing will be avoided, too. Another film coating process for aluminum mirror sheet pieces is called laser cutting. The sheet is resistant to high temperature and does not stick to the aluminum plate like a normal protective film after cutting. The last is a direct coating of the mirrored aluminum surface. The surface of the aluminum plate is cleaned by water, dilute acid and alkali solution, during which the cleaned aluminum plate is vacuum coated with ceramic material, and a film forms on the surface of the aluminum sheet. This film layer is not only colorful, beautiful, corrosion resistant and wear resistance, but also sturdy; and the method is simple in process, less polluting to the environment, and low in production cost, which is conducive to large-scale industrial production.

评论

发表评论