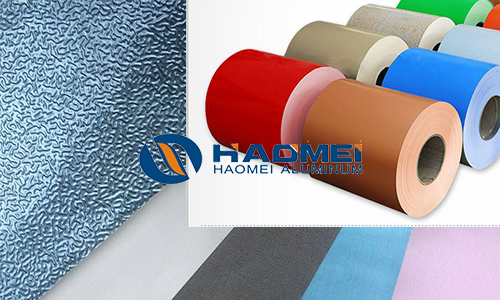

Aluminum roof coil stock

Haomei aluminum roof coil stock, usually color coated, can be of 1xxx or 3xxx series. 3003, 3004 or 3105 aluminum coil stock is commonly used for conventional roof slabs, while 1100 or 3003 is for embossed aluminum roofing coils. The regular widths for smooth-surfaced roof coils include 1000mm, 600mm and 575mm, and embossed ones from 1200mm to 1600mm. Specific width can be customized according to your requirements. The coating thickness for smooth stocks is 0.8mm or 0.88mm, but that for embossed stocks are much thicker, from 0.25mm to 0.5mm. Available paints cover pe (for embossed coils), pvdf (for smooth coils) and pvc. The color of gray, silver gray or flash silver is commonly used for conventional roofing panels that are double-coated, and the back coating is generally white; Embossed aluminum coils, with orange peel or diamond pattern, are usually black, brown or white, according to customer requirements.

Surface treatment steps for our aluminum roof sheet coil stocks are as below: 1) Anodized aluminum plate (usually imported, domestic technology is immature) 2) Powder spraying treatment 3) Fluorocarbon spraying treatment Anodizing VS powder vs Fluorocarbon aluminum plate curtain wall basic knowledge tutorial! Hurry up and collect! ⑦Fluorocarbon spraying process: fluorocarbon (PVDF: polyvinylidene fluoride) spraying: after aluminum sheet blanking and processing, enter the surface treatment production line. The standard procedure is: pre-degreasing → degreasing (alkali washing, strong alkali washing to remove oil stains ) → 2 water washing → pickling (deoxidizing film) → water washing → chromizing (or phosphating, passivation to form an oxide film → water washing) → 2 pure water washing → drying → strong cooling → spray primer → spray paint (Color paint) → baking → (strong cooling → spray lacquer → baking).

Haomei aluminum roof coil stocks, with stable performances in corrosion resistance, are widely used in civil construction. Aluminium-magnesium alloy coil stocks for roofing and exterior walls generally adpot the pre-roll coating process, which has the advantages of good color difference control, uniform paint film, high quality stability, and environmental protection. The coating type is generally PVDF fluorocarbon paint with 70% or more of fluorocarbon resin.

Reprinted from https://www.aluminum-coil.net/aluminum-roof-coil-stock.html

评论

发表评论