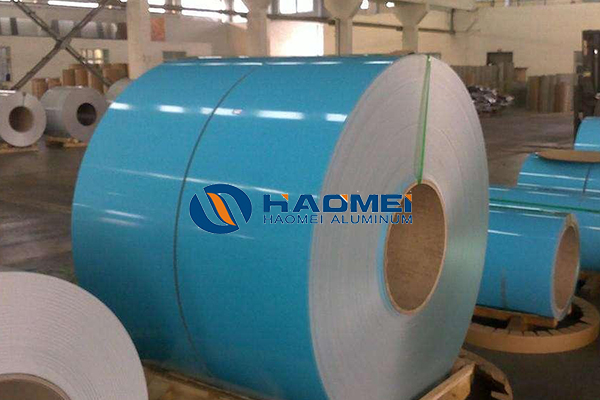

Aluminum siding coil stock

The general thickness of aluminum siding coil stock ranges between 0.10mm and 8mm. Tempers include O, H18, H22, H24 etc, from soft to hard. Its application scope is as wide as its alloys that incorporate 1050, 1070, 1100, 3003, 5052, 5083 and so on. Representative uses comprise aluminum plastic panels, interior decoration, exterior decoration, road signs etc.

1000 series of aluminum alloy coil stocks, like 1100 aluminum coil, have a weaker strength in comparison with alloys of other series, because 99% of its content is aluminum. Owing to high aluminum content, it’s also referred to as pure aluminum. Pure aluminum displays good ductility, that’s why aluminium coil stock can be processed into extremely thin aluminum foils for food wrapping, air-conditioning etc. Once exposed to the air, aluminum has chemical reaction with oxygen quickly, producing a layer of protective material against further oxidation or other active elements. Alloyed aluminium of 3xxx and 5xxx feature an even stronger corrosion resistance. Although 5000 series, represented by aluminum coil 5052 and 5083, are normally regarded as anti-rust series, 3xxx aluminium shows excellent rust resistance as well. High heat and electric conductivity widens its application scope to household industries. The most important factor for its popularity, however, falls on low cost. Further more, its recyclable value is much higher than iron or steel. It takes less money and procedures to reuse it.

Aluminum siding coil stocks of 1xxx, 3xxx and 5xxx mentioned above are mill finished. The fact is they can also be anodized, color coated, polished and even embossed to cater for various application requirements. Considering the natural conditions their end products will face, further surface treatment is necessary. Anodizing helps to improve the weather resistance and hardness of a coil stock, polishing and embossing makes it more beautiful, and color coating does both. The price of a type of siding aluminum coil stock for sale varies with its alloy and surface treatment methods as well.

评论

发表评论