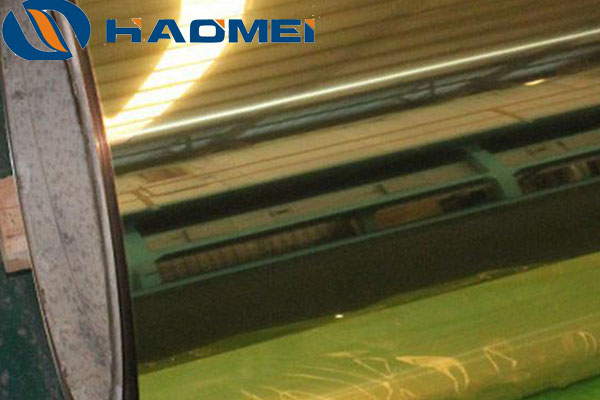

Polish aluminum coil 3003

Polish aluminum coil 3003 is of tempers O, H16, H14, H18 and H19. Its thickness ranges between 0.02mm and 3mm, and width from 100mm to 1600mm. 3003 aluminum alloy is an alloy in the wrought aluminum-manganese family (3000 or 3xxx series). Approximately 20% stronger than alloy 1100, it is readily formed by either conventional cold working or hot working. It can be cold worked (but not, unlike some other other types of aluminum alloys, heat-treated) to produce tempers with a higher strength, but a lower ductility. Haomei offers 3003 coil covered by the ISO standard 6361 and the ASTM standards B209, B210, B211, B221, B483, B491, and B547. Commonly used tempers include H14, H16 and H18 while others are also available by customers’ demands. The 3003-H14 is a softer, more formable aluminum coil.

Polish aluminum coil 3003 has very good corrosion resistance, moderate strength and excellent weldability, formability and machinability. It is commonly rolled and extruded, but typically not forged. As a wrought alloy, it is a is popular and economical choice in appliance components, commonly used in sheet metal applications such as HVAC, condenser, radiator, evaporator, heat shield, gutters, downspouts, truck and trailer roofing, cooking utensils, pressure vessels, refrigerator panels, gasoline tanks, heat exchanger, furniture components and siding.

3003h24 polish aluminum coil proves to be a good material for curtain walls. It’s of 0.5mm to 3.0mm thick and 900mm to 1400mm wide. Nevertheless, 3003 coil is not applicable to anodizing process, by which colors can be made on a coil surface. Therefore, colored polish aluminum coil rolls are usually of 5000 series rather than 3000 series.

Reprinted from https://www.aluminum-coil.net/polish-aluminum-coil-3003.html

评论

发表评论