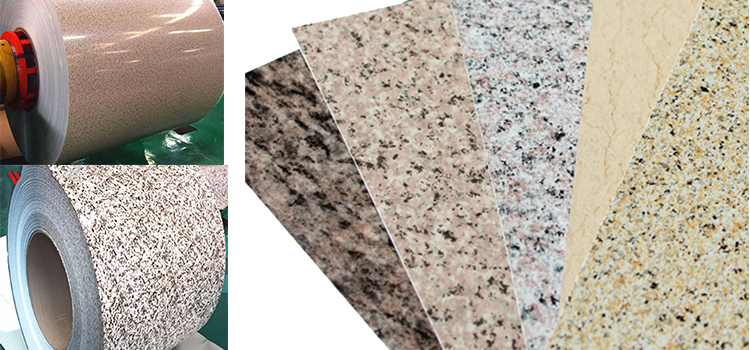

Stone coated coated aluminum coils

Among leading aluminum manufacturers and suppliers in Henan, China, Haomei supplies 110, 1050, 3003, 5005, 5052 stone coated coated aluminum coils of PE and PVDF. Thickness is 0.024mm to 1.2mm, and width 50mm to 1700mm. Alloys are 1100, 1050, 1060, 3003, 3004, 3005, 3104, 3105, 5005, 5052, 8011.

| Paint type | PVDF POLYESTER ACRYLIC |

| Thickness | 0.024mm-1.20mm |

| Width | 50mm-1700mm (Standard width:914mm, 1000mm, 1219mm) |

| Coils core diameter | 150mm, 305mm, 405mm, 505mm, 508mm, 510mm POLYESTER>=17micron |

| Coating thickness | PVDF >=25micron |

| Gloss | 10-90% |

| Coating hardness(pencil hardness) | More than 2H |

| Coating adhesion | No lower than first grade |

| Impact resistance | No cracking and peeling(50kg/cm, ASTMD-2794:1993) |

| SheetMEK resistance: | More than 100 times |

| Advantage | Flexibility |

| Usage | Aluminum composite panel, ceiling, door and windows, electric appliance,etc. |

| Temper | O,H12,H14,H16H18,H19,H22,H24,H26, H28,H32,H34H36,H38, H42 H44 |

| Alloys number | 1100, 1050, 1060, 3003, 3004,3005,3104, 3105, 5005, 5052, 8011 |

| Application | ACP, aluminum, ceilings, aluminum sheets, honeycomb panels and aluminum roofing, lighting decoration, Household electrical appliances, food package (such as pop can cover & ring-pull), furniture ect. |

| Item | Test Item | Standard | National standard | Test Result |

| 1 | Color Difference | ECCA T3 | ΔE≤2.0 | ΔE≤1.5 |

| 2 | Gloss Difference | ECCA T2 | ≤10 | ≤5 |

| 3 | Coating Thickness | ECCA T1 | Two layers Min 23μm | ≥25μm |

| Three layers Min 30μm | ≥34μm | |||

| 4 | Pencil Hardness | ASTM D3363 | ≥HB | HB |

| 5 | T-bend | ASTM D4145 | ≤2T | ≤2T |

| 6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | ASTM D2794 | ≥50kg.cm | ≥50kg.cm |

| 8 | Boiling water Resistance | GB/T17748 | 2h No change | 4h No change |

| 9 | Solvent Resistance | ASTM D2248 | 200 times paints remaining | 500 times no break |

| 10 | Acidity Resistance | ASTM D1308 | 5%HCL 24hrs No change | No change |

| 11 | Alkali Resistance | ASTM D1308 | 5%NaOH 24hrs No change color △E≤2.0 | No change |

| 12 | Nitric acid Resistance | AAMA620 | △E≤5.0 | △E≤5.0 |

| 13 | Oil Resistance | ASTM D1308 | 20#oil 24hrs No change | No change |

| 14 | Salt Spray Resistance | ASTM B117 | 4000hrs ≤Grade 1 | No change |

| 15 | Abrasion resistance | ASTM D968 | ≥5L/μm | ≥5L/μm |

| 16 | Dirt Resistance | GB/T9780 | ≤5% | <5% |

| 17 | Color retaining | GB/T16259 | 4000 hrs△E≤4.0 | 4000 hrs △E≤3.0 |

| 18 | Gloss weaken Level | 4000 hrs ≤ Grade 2 | 4000 hrs ≤ Grade 2 | |

| 19 | Chalking | 4000 hrs No change | 4000 hrs No change |

| Chemical Composition % | ||||||||||||

| Alloy No. | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | V | Ti | Zr | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | – | – | 0.05 | 0.05 | 0.03 | – | Remainder |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | – | – | 0.05 | 0.05 | 0.03 | – | Remainder |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | – | – | 0.04 | 0.05 | 0.03 | – | Remainder |

| 1100 | Si+Fe:0.95 | 0.05-0.20 | 0.05 | – | – | – | 0.01 | 0.05 | – | – | Remainder | |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | – | – | – | 0.1 | – | – | – | Remainder |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | – | – | 0.25 | – | – | – | Remainder |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.2 | – | 0.4 | – | 0.1 | – | Remainder |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5-1.1 | 0.1 | – | 0.25 | – | – | – | Remainder |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | – | 0.1 | – | – | – | Remainder |

| 5083 | 0.4 | 0.4 | 0.1 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | – | 0.25 | – | 0.15 | – | Remainder |

| 5086 | 0.4 | 0.5 | 0.1 | 0.2-0.7 | 3.5-4.5 | 0.05-0.25 | – | 0.25 | – | 0.15 | – | Remainder |

| 5182 | 0.2 | 0.35 | 0.15 | 0.2-0.5 | 4.0-5.0 | 0.1 | – | 0.25 | – | 0.1 | – | Remainder |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | – | 0.25 | – | 0.15 | – | Remainder |

| 6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.90 | 0.1 | – | 0.1 | – | 0.1 | – | Remainder |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.25 | – | 0.2 | – | 0.1 | – | Remainder |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.20 | – | 4.0-5.0 | – | 0.01-0.06 | 0.08-0.20 | Remainder |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | – | 5.1-6.1 | – | 0.2 | – | Remainder |

| 8011 | 0.50-0.90 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | – | 0.1 | – | 0.08 | – | Remainder |

Reprined from

评论

发表评论